Leaderboard

-

in all areas

- All areas

- Markers

- Marker Comments

- Marker Reviews

- Articles

- Article Comments

- Article Reviews

- Classfieds

- Classified Comments

- Classified Reviews

- Wiki's

- Wiki Comments

- Wiki Reviews

- Blog Entries

- Blog Comments

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Files

- File Comments

- File Reviews

- Posts

-

Custom Date

-

All time

November 28 2011 - July 14 2025

-

Year

July 14 2024 - July 14 2025

-

Month

June 14 2025 - July 14 2025

-

Week

July 7 2025 - July 14 2025

-

Today

July 14 2025

-

Custom Date

11/10/2016 - 11/10/2016

-

All time

Popular Content

Showing content with the highest reputation on 11/10/2016 in all areas

-

10 pointsMounted the grader blade on the C195 yesterday. it works good in the back driveway for gravel.

-

10 pointsIf you are a Marine you know what today is. On your person you see a stamp of two yellow footprints with the inscription "Property of USMC" Born on 10 November, 1775. This is the day every Marine was made. So here to you and are Corps Happy Birthday.

-

10 pointsOne of the biggest points of wear are those front steering spindles . I've rebuilt many front axles and it's the same issue every time - the bottom section of the spindle never receives enough grease to go all the way around the shank and it becomes galled over time . Dealing with my D series right now which also uses roller thrust bearings . One is so bad it galled the destroyed bearing onto the spindle so it must be replaced . Most front axles at minimum have to be bored and sleeved with bronze sleeve bearings which can be a pain and gets expensive . My advice - spend an extra minute or two and jack up the front axle to take the weight off those spindles , then grease and cycle the steering with it unloaded . Be careful to avoid putting the jack on the grease zerk that feeds the axle center pin . Best way is to pick it up by the frame with a spreader beam fitted to the jack so the weight is off that center pin as well . I dealt with heavy equipment and trucks for years replacing spring bushings and kin pins - you could tell which ones were jacked up before greasing since they lasted far longer before any wear developed . Sarge

-

6 pointsI am getting out of the changing implements business. This C120 (formerly C160) is now permanently married to a 50In midmount. added ag tires and weights she should do well at grading. and for the 2-3 hours use a year she should last a long time. The Elcectro 12 in the back ground will be permanent backup plow tractor.

-

6 pointsOk, there is no way that I'm the first guy to do this. I was looking for a replacement for my destroyed steering wheel. The options to fit the shaft were few and I thought a bit expensive. Thinking back to when I raced dirt track, I had a brain storm. Or a slight drizzle. A steering wheel quick connect is a 3/4" shaft. $25 for the quick connect and $32 for a Grant classic wheel. No modification made to the shaft. I drilled a hole in the coupler for a roll pin. I might rig a spot weld on it. Cool thing is if the wheel is in the way while doing maintenance, it takes half a second to rip it off. Mark.

-

6 pointsMy wife and I spent the day at "Flywheeler Park" at Avon Park Florida, Got to hang out with old friends and saw some neat stuff; enjoy. This is a "Fromall" which was built with parts From All Sorts of Stuff !

-

5 pointsOld age starting to get me. An excellent excuse to have more Horses! 1 or 2 for mowin'. 2 for snow removal. 3 or 4 for grandsons; wagon rides, leaf sweeping, races, rolling the lawns. 2 automatics for granddaughters, mailbox runs and keeping tabs on the boys. Simple enough.

-

5 pointsLooks and bet it is an excellent implement. I use my Allis-Chamers blade on my stone 'n millings driveways.

-

5 pointsmmmmmdonuts very good advice but be carefull about the amount of grease you put into the pto bearings, too much and it will creep out and get on the friction surface and cause the pto to slip don't ask how I know this.

-

5 points

-

3 pointsHello all Richy in West Wales here. I collected my Wheel Horse today - bought from a classic car /automobilia auction a couple of weeks back. I'm new to this - can anyone tell me about this model please, as I'm clueless so far!

-

3 pointsFor the first time in my 40 year old life, I changed oil, gear oil, a fuel filter, and an air filter. Woot! Now I am looking to rewire my headlights and apply some grease. I was just going to grease the spindles, but I noticed some grease plugs on each side of the back axle. Is there anywhere else that I should think about greasing? Is there any other maintenance that I should learn? Thanks guys!

-

3 pointsI saw the comment that the two stage and single stage used the same cranks. Here is a picture of my two. Top (silver) is from my two stage and the bottom (Black) is from my single stage. Same dimensions but the single stage has a rotating handle. Here are the dimensions Also, my two stage has a longer connection tube so that the crank can be used with a cab. Kurt My two stage was missing the sway bar also, so I made my own. I used some 1/2" HMW Poly for the rub block. It works just fine, but limits the opening of the hood. Kurt

-

2 pointsI just got finished making up a crank rod to turn the snow thrower chute on my 520-HC with a Ber-Vac snow thrower. Here are some pics of how I did it. I am very pleased with the results. I used a 3/8 drive universal and a 3/8 drive extension. My neighbor welded the extension into a piece of 1/2 inch conduit and the universal into a piece of 3/4 inch conduit. Then he welded the original crank handle in the other end of the 1/2 inch conduit. The universal snaps into the extension giving me the flexible joint I need for the angle and also it's easy to remove when I remove the snow thrower with no tools. I can let the universal attached to the snow thrower. The 3/4 conduit has a 3/8 hole drilled in it for a bolt to fasten it to the chute gear on the snow thrower. The 1/2 inch conduit fits perfectly in the hole on the support bracket attached to the tractor. All I need to do now is make an attachment for the lift assist springs on the front quick hitch bracket.

-

2 pointsWith all the talk about snow plows of late and winter on the way I thought I would share a few parts I decided try and make and I think they turned out pretty nice...the adjustable skid shoes for keeping the cutting edge/wear bar up out of gravels or grinding off on asphalt/concrete the factory O.E. are sand blasted black the ones I made still raw steel then painted black on the plow ,and the rear axle quick hitch black factory and raw steel I made the locking keys if you look close enough the pitted one's are original and non pitted I made, Jeff.

-

2 pointsPackage deal like that around here in VA would go for $2500+/-, I just got one with a bagger with 560 hrs for $1000 another in the spring with just a deck $1200 the 2stage blower $250 last fall and my tiller (which BTW will leak from the gearbox perpetually) $300 5-6 years ago but that depends on the shape of the tines so let's say $1200 tractor with deck + $300 blower + $300 tiller and a cab another $200 so depending on your area $2000+ would be fair for the whole package, then ask yourself what would $2000 get you at Lowe's or Home Depot just my opinion,. Oh I just saw the rear clevis hitch and disc and turnover moldboard plow an aerator and front mount dethatcher and yard cart HOPEFULLY you get all that (anything that fits or for use with that wheel horse) too!!!, great find,Jeff.

-

2 pointsSorry about the Cubs but seriously, I believe there is a (other brands) section if you wish to discuss them. Oh and by the way to and don't be afraid to ask for any help with your 520 it is a nice machine and there is lots of information and good people here on Redsquare to answer any questions you might have.

-

2 pointsDoes luck follow you! Don't mess around asking a bunch of questions about the C160 or it won't follow you for long! Go get it! Ask questions later!

-

2 pointsJust an update. Finally got all the pieces blasted, primed and painted. Now the real challenge sets in....Waiting for the paint to cure before starting to put it back together. Also, any suggestions on seats is appreciated. The recipient of this tractor, my son-in-law, is about 6'4 and 240 lbs, so I need to find a seat with good suspension and one that can be mounted far enough back so he won't be too cramped. I have a stack coming from @jimkemp so that decision is made. I was going to add more white accents but the SIL wanted all red, except the wheels of course. It seems that the disassembly and reassembly are the fun parts. The blasting, grinding and priming is monotonous...Painting isn't bad because you know the reassembly is getting near, but then that impatience gene kicks in.... Tempted to start tearing down the 856, but wisdom says not to have two tractors torn apart at the same time..... Oh...and...the pics. Rough count is about 200 individual pieces to blast, prime and paint, for the tractor alone......

-

2 pointsNo Dennis. I dont know for sure what years but I parted out a 90 that had swept axle and no gear reduction.

-

2 points

-

2 points11-10-1969 Sesame Street debuts On this day in 1969, “Sesame Street,” a pioneering TV show that would teach generations of young children the alphabet and how to count, makes its broadcast debut. “Sesame Street,” with its memorable theme song (“Can you tell me how to get/How to get to Sesame Street”), went on to become the most widely viewed children’s program in the world. It has aired in more than 120 countries. The show was the brainchild of Joan Ganz Cooney, a former documentary producer for public television. Cooney’s goal was to create programming for preschoolers that was both entertaining and educational. She also wanted to use TV as a way to help underprivileged 3- to 5- year-olds prepare for kindergarten. “Sesame Street” was set in a fictional New York neighborhood and included ethnically diverse characters and positive social messages. Taking a cue from “Rowan and Martin’s Laugh-In,” a popular 1960s variety show, “Sesame Street” was built around short, often funny segments featuring puppets, animation and live actors. This format was hugely successful, although over the years some critics have blamed the show and its use of brief segments for shrinking children’s attention spans. From the show’s inception, one of its most-loved aspects has been a family of puppets known as Muppets. Joan Ganz Cooney hired puppeteer Jim Henson (1936-1990) to create a cast of characters that became Sesame Street institutions, including Bert and Ernie, Cookie Monster, Oscar the Grouch, Grover and Big Bird

-

2 pointsGot another good spark plug you can try? I always keep a spare new one for times like this. Try it and if it works leave it there. If it still doesn't run I remove the new plug and save it for the next time. Weak plugs will fire out of the head but can fail under compression. Garry

-

2 points

-

2 pointsWelcome to Red Square - Looks like you found a great deal on a nice 520H. I agree with some others. If it overheating, I would you pull the engine shrouds and clean the cylinders and heads. Most likely it packed with oil, dirt, and grass. Especially the rear cylinder. Even if it wasn't overheating, I would suggest you do that. Lots of help here if you decide to get it. Kurt

-

2 pointsThe lift assist spring is important with hydro lift as well as it allows the blower to float more and helps it from digging down into the ground on gravel and should actually help with steering to a point as it is pulling up on the blower. Also without it the blower lifts crooked with the right side barely lifting off the ground.

-

2 pointsOne of the more desirable WHs. I really don't need it but I DO desire it. Most all C, 300,400 and 500 series attachments will fit, though as already noted the dozer blade will need extension. This is because it has a forward swept axle that will also accommodate the 60" deck. I'm guessing you'll have to spend some time pulling the engine tin off and blowing out fins. My 2 cents from mowing with my 416 Onan is that there are better engine choices for mowing. Mine is however a great leaf and grass cutting collector! Seems they all try to gather on the engine shroud! Won't help with engine cooling! And if I might interject a question, guys, does the swept axle also mean steering gear reduction? Either way I'm pretty sure I'd have to buy it! Hubcaps, weights and if that was a 48" deck? Yep! Silly match up IMHO to put a 42" on that 20 hp beast!

-

2 pointsNice Horse! Yes, 48" SD deck, height adjustment on the right. Be sure to clean all the engine and trans fan. Post your progress, we Horses' need updates!

-

2 points

-

2 pointsCertain case of Wheel Horse Addiction. A good thing! Does the Ms. believe the, "Followed me home." story thingy?

-

1 point

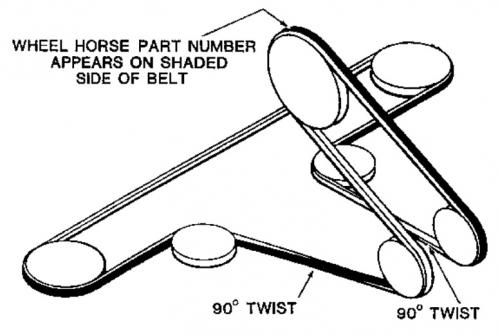

301 downloads

2 pages 100.29KB Belt installation instructions for the six-sided belt used on the 05-37SC01 - all pulleys are V-pulleys Drive and spindle belt 111178 (1/2" x 140.5") Six-sided double-V belt [265-001 Stens] The 05-37SC02 deck used a regular 4-sided belt with flat idler pulleys for the back side of the belt. Drive and spindle belt 110265 (1/2" x 141.00") Fits 300 400-Series tractors Mower Rotary 1986 37in SD model 05-37SC01 Mower Rotary 1987 37in SD model 05-37SC01 Mower Rotary 1988 37in SD model 05-37SC01 Mower Rotary 1989 37in SD model 05-37SC01 Mower Rotary 1990 37in SD model 05-37SC01Free

-

1 pointHey guys, I've started the restoration of my 1968 Raider 10. I originally found that they didn't make a Raider 10 in 1968 but through discussion with the experts here, we determined that my tractor was a 1968 that was badged a Raider 10 with the 10 HP Tecumseh. Here's the starting point picture. It was in better shape a few years ago but it was a slight casualty to hurricane Sandy. Nothing is rusted through, thankfully. It's unfortunate that it happened and I never expected it to get wet where it was. We were at least a 1/4 mile from the water -- probably more -- but, I came to work (where it was stored) the following day and we had a garbage dumpster from the business across the street and a boat dock in out parking lot...It was insane and very unexpected. Anyway, I've disassembled a bunch of it and will e-tank the crap out of everything.

-

1 pointOk, im new to Wheel Horses and I'm in love - I picked up a D-200 a few months ago for super cheap ($150) and sold it a week later when someone offered me a pile of cash. I regret selling it but after some research I found a 520h for sale (pic attached). It has 800 hours, looks like it has been taken care of, and comes with a box blade and wheel weights and a 42 inch deck. I'm told that it overheats a bit after 30 minutes but I'm thinking there is a fix for that. My questions are what all attachments will this thing take and is it really the beast that I've heard that it is? I know its not a D-200 but I want to be able to hook up about anything and be able to work. I wouldn't be working it daily - mostly just weekend stuff on my 8 acres. A little bit of everything, plowing, discing, tilling, grading, and mowing - thanks in advance for the advice!

-

1 pointFix a flat is nasty when you do go to replace tires. I would echo Tankman's comment and get new tires with tubes...I just did it this past year and am very glad I did...

-

1 pointI did not, Toro calls for the 110265 for the newer style belt tighter then depending on if you have a single cylinder engine or twin cylinder engine will determine witch hole you use in the bracket- the reason? So you only need the 1 belt

-

1 pointOn the advice of @squonk I wire brushed a 50 year old deck and sprayed with Loctite Extend Rust Neutralizer Once cured, I sprayed with truck bed coating It turned out great. It appears to be a durable solution. Note: In order for the neutralizer to work, rust must be present. So if you take it down to bare metal, this isn't the solution for you.

-

1 pointMine didn't come w a lift rod or sway bar and bumper. I was able to borrow a lift bar to copy. Works great! I finally found a sway bar, bumper & belt guard assembly. Haven't ever installed any of them. It's one less thing to mess around with. It's been a few years now and I haven't had any problems without those pieces. im open to suggestions for installing the lift spring. I use a hydro and thought it unnecessary.

-

1 pointHad an 8 hp, did it all too. Plowed snow and earth to the amazement of doubtful neighbors.

-

1 pointfirst thing I would do if I were you, is kiss your wife , An opportunity like that doesn't happen to all WH owners everyday . Good luck when you come down to earth. Great find

-

1 pointFind some retired dude with a 4-jaw chuck and at least a 10" lathe - have it tig welded with 70-80 series filler rod and then turn the diameter back to original , not that hard . For the axle itself , I use a bridge reamer 1/8" larger than the spindle and order up bronze sleeve bearings , turn those to fit the axle with a slight gap , drill/groove it for grease and eliminate 95% of the wear , permanently . Sarge

-

1 pointSarge is right.Jack up the front when you grease the spindles.I do this on all my tractors.On the big ones like the Ford 3400 industriaI I raise one side at a time.Well worth the effort.JAinVA

-

1 pointDon't think I got that sway bar thingy Jeff...or that rubber thingy on the front. After studying your pics & the IPL more I think ther is a 520 running around out there with my parts on it. Count me in if you have one available. You guys know how it is that never fails to amaze us how these things get left behind on a tractor or ditched by a PO. More pics in the AM ....thanks for the help fellas. Oh BTW Billy that last pic makes me want it to snow bigtime...that beast has gotta be throwing it 40 yards!

-

1 pointThe crank rod is the same from a single stage tall chute I know that for sure (I made an extension to bring mine closer into the cab, did you get the frame mounted rear belt guard/sway bar support (1st pic) if not I have one available and sway bar (2cd pic) I don't have an extra 1 of those? Then you'll be chucking snow like the last pic,Jeff.

-

1 pointPhil, Can you take a close up of the hood decal close to the front? Looking to see where that shop is/was

-

1 pointWelcome to the square nice tractor not an expert on 520's but I believe that is a 48" deck if cut adjustment is on the left 48", on the right 42". Have fun

-

1 pointIt came with a deck, snow thrower, a rear blade (I think that's what it is - no numbers) and here are the pics. The deck is in really good shape -- no rust through anywhere and it's very solid. All of the wheels are there and work. The snowblower/thrower is in great shape as well. A little bit of surface rust but that's it. The cable is there and properly installed so the chute works great. The blade is a rear blade, I think. There are no numbers on it so I can't really tell. Any ideas? Just a really small front blade? I think I'm missing the mount for it. It looks like it is a manual angle adjustment type of thing. Thanks! Sounds good! I'll be sure to record this resto as best I can. I'm going to clean it up and see what the deck looks like. I think I probably will, though. I'm going to be using the electrolysis tank on the rear fender this week. I'll have before and after pics.

-

1 pointIDK, I see wrong parts and engines in there for what's shown in those pics for a "pricey" score. I'm not a big Lawn Ranger fan and don't really think they have the "round hood" value as the other round hood tractors do. They've certainly been sitting there for a loooooooooooong time. Guess it also depends on what you consider "pricey" too, as that's a completely different sum to different people.

-

1 pointImagine what this guy... could accomplish using a comfy chair. 2017 BIG SHOW or BUST!!!

-

1 pointDeck assembled, decals installed, blades balanced and installed. Installed deck onto 520-HC. Still need to test out bagger whenever grass starts to grow.

-

1 pointLooks good, I like your idea. Don't forget to replace the shifter boot as you clean up the rest of the tractor.

.JPG.9f2ecb26065c66527b0730084ab7fc7a.thumb.jpg.7dc8a04d9a53d44ee2b23f26ee94496f.jpg)